Radiant Panel Heating & Cooling Systems

Overview

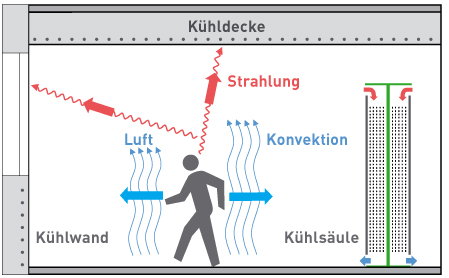

The cooling and heating surfaces work with a surface temperature of 19 °C for cooling and only 26 °C to 29 °C for heating so that even in the heating mode, energy emitted by humans is transmitted to the ’active’ room surfaces. This results in a constant gentle radiant exchange between both.

Quelle: Prospekt Firma Clina

The heat exchange takes place at 60% of radiation and 40% of convection (air-current). This corresponds to the natural heat regulation of the human body. It is proven that the well-being and productivity of people in such environment is increased.

Due to the large exchange surfaces, also at small differences between the active surfaces of the room and the room air (maximally 5 °C), large amounts of energy are transferred without drafts and noises of conventional systems.

| Type | System Components / Features / Advantages | Specific Output |

|---|---|---|

| PP-Combi |

|

Cooling output: 60 W/m² Thermal output: 42 W/m² |

| PP-Inside |

|

Cooling output: 97 W/m² Thermal output: 55 W/m² |

| Single-Combi |

|

Cooling output: 62 W/m² Thermal output: 76 W/m² |

| Cu-Combi |

|

Cooling output: 80 W/m² Thermal output: 96 W/m² |

| Type | System Components / Features / Advantages | Specific Output |

|---|---|---|

| PP-Meta |

|

Cooling output: 87 W/m² Thermal output: 82 W/m² |

| Single-Meta |

|

Cooling output: 73 W/m² Thermal output: 93 W/m² |

| Cu-Meta |

|

Cooling output: 93 W/m² Thermal output110 W/m² |

| Type | System Components / Features / Advantages | Specific Output |

|---|---|---|

| PP-Ultra |

|

Cooling output: 93 W/m² Thermal output: 65 W/m² |

| PP-Film-Ultra |

|

Cooling output: 97 W/m² Thermal output: 67 W/m² |

| Single-Ultra |

|

Cooling output: 85 W/m² Thermal output: 88 W/m² |

| Type | System Components / Features / Advantages | Specific Output |

|---|---|---|

| PP-Floor |

Under the floor covering:

In cement screed or flowing screed:

|

Cooling output: 32 W/m² Thermal output: 50 W/m² |

| PP-Film-Floor |

|

Cooling output: 32 W/m² Thermal output: 55 W/m² |

Capillary Tube Systems

The capillary tube mats are integrated either under layers of plaster (PP-Ultra), in the floor (PP-Floor), on drywall panels (PP-Combi) or inserted in metal cassettes (PP-Meta) into the room enclosing surfaces like ceiling, wall and flooring. There they are connected hydraulically to the supply and return lines. The hydraulic systems consist of corrosion resistant materials (polypropylene, copper or stainless steel). Both heating and cooling is provided by just one pipe system.

The thin parallel-guided capillary tubes (4.3 x 0.8 mm) are incorporated homogenously into the distributor/collector and welded into mats. Spacing strips (Omega strips) ensure the parallel distance of 10 – 30 mm between the capillary tubes. The capillary tube mats, pipes and fittings are made of polypropylene. Polypropylene copolymer (random copolymer type 3) has a high molecular weight and is characterized by its high tensile strengths, hardness and stiffness. And, the used synthetic material has a useful economic life of more than 50 years.

Materials made from PP comply with the requirements of fire classification B2 according to DIN 4102 T2 and are, therefore, normally flammable. Since PP is composed exclusively of carbon and hydrogen atoms, during combustion no pollutants are emitted.

One feature of the capillary tube systems is the oxygen diffusion through the polypropylene capillary tubes and fittings. The oxygen exchange between the ambient air and the circulating water takes place until the oxygen saturation point is reached.

To protect the system against oxygen caused corrosion and accumulation of mud; the power generation circuit are separated hydraulically from the capillary tube circuit by insertion of a heat exchanger.

These results in two independent hydraulic circuits: the primary circuit carrying the heating and/or cold water generator and the secondary with the capillary tube system. The secondary circuit is 100% corrosion resistant and, therefore, it has a very long duration of life.

Flexible Tube Systems

The flexible tube systems are integrated either into layers of plaster (Single-Ultra), on drywall panels (Single-Combi) or in metal ceilings (Single-Meta). Since the tubing is made of oxygen-tight material it can be connected directly to the existing tubing system even if it is not corrosion resistant.

However, a separation system and corrosion resistant feed lines at the secondary (supply line to the radiant panel heating) are always recommended. Only a separation system and corrosion resistant supply lines guarantee a long duration of life.

The tube system is characterized by its high flexibility and adaption to built-in components in the active areas. Changes of the system on a short notice can be done on site. The tubes of the Single-Combi and Single-Meta-System are integrated into an aluminium heat conducting profile. This results in an optimal heat conducting contact between the radiant ceiling system and the hose.

Copper Systems

The copper systems are suitable for drywall ceilings (Cu-Combi) or metal ceilings (Cu-Meta). These systems are particularly suitable for rooms with increased fire safety requirements. Since the system is oxygen tight, it can be connected to any other piping system.

Control

In combination with the climate system, an appertaining control system should be used to regulate the supply temperature for heating and cooling and for room temperature control. To prevent damage to the surfaces caused by condensation water, a dew point sensor should be installed.